Discover the 7 major advantages of industrial automation. Optimize your operations with AI-powered software to reduce costs and improve safety.

Why Industrial Automation Is Crucial to Staying Competitive Today

In a constantly evolving economic environment, businesses must overcome increasingly complex challenges. To do so, they need to weigh the key benefits and drawbacks of automation. Industrial automation technologies now offer efficient, scalable solutions. Process automation has become essential.

Thanks to intelligent software, automated systems, AI, and robotics, it is now possible to reduce operational expenditures, streamline industrial workflows, and increase productivity while simultaneously enhancing safety and product quality.

But what are the concrete benefits of industrial automation for companies in Quebec and across Canada?

1. Process Optimization for Greater Productivity

One of the most significant advantages of automation is the ability to optimize large-scale operations. Automating tasks accelerates execution, reduces human error, and boosts overall output.

Automated systems allow equipment to run continuously, without downtime, something manual operations cannot achieve.

By automating production lines, companies can produce more, at higher quality, and with greater speed.

2. Reduce Operational Expenditures

Automating processes significantly reduces expenses tied to labor, production errors, material waste, unplanned maintenance, and energy inefficiencies.

Automation software or an AI-powered system can detect anomalies in real time, anticipate failures, and prevent unplanned downtime.

The result: more efficient operations and measurable savings across the board.

3. Empower Employees by Automating Routine Tasks

Automation eliminates tedious, repetitive work, allowing employees to focus on higher-value activities. This shift boosts both productivity and satisfaction.

Workers can then focus on more creative, analytical, or strategic responsibilities—areas where their skills are most valuable.

Automation does not replace people; it elevates human potential while acknowledging the pros and cons of automation.

4. Improve Quality Through Standardized Processes

By standardizing workflows, automation eliminates operator-dependent inconsistencies. Quality is stabilized, data is logged in real time, and production parameters remain precisely regulated. It minimizes defects, ensures automatic data capture, and maintains strict control over production settings. Errors are reduced, data is recorded automatically, and production parameters are tightly controlled.

This is particularly crucial in industries where compliance is non-negotiable, such as agri-food, pharmaceuticals, or manufacturing.

Companies that automate often report fewer non-compliances and significantly better traceability. Errors are reduced, data is recorded automatically, and production parameters are tightly controlled.

Such consistency is particularly crucial in industries where compliance is non-negotiable, such as agri-food, pharmaceuticals, or manufacturing.

Companies that automate often report fewer non-compliances and significantly better traceability.

5. Increased Operational Flexibility

With the right software and control systems, businesses can reap the full benefits of automation. They can automate multiple production scenarios, adjust output to match demand, and reconfigure equipment quickly and easily.

Modern industrial automation is no longer rigid. It is modular, flexible, and scalable.

An automated line can handle multiple formats with fast, precise changeovers.

6. Enhanced Workplace Safety

Dangerous or physically demanding tasks can be automated to significantly reduce the risk of workplace accidents. Machines take over hazardous tasks, allowing operators to supervise remotely and step in only when needed.

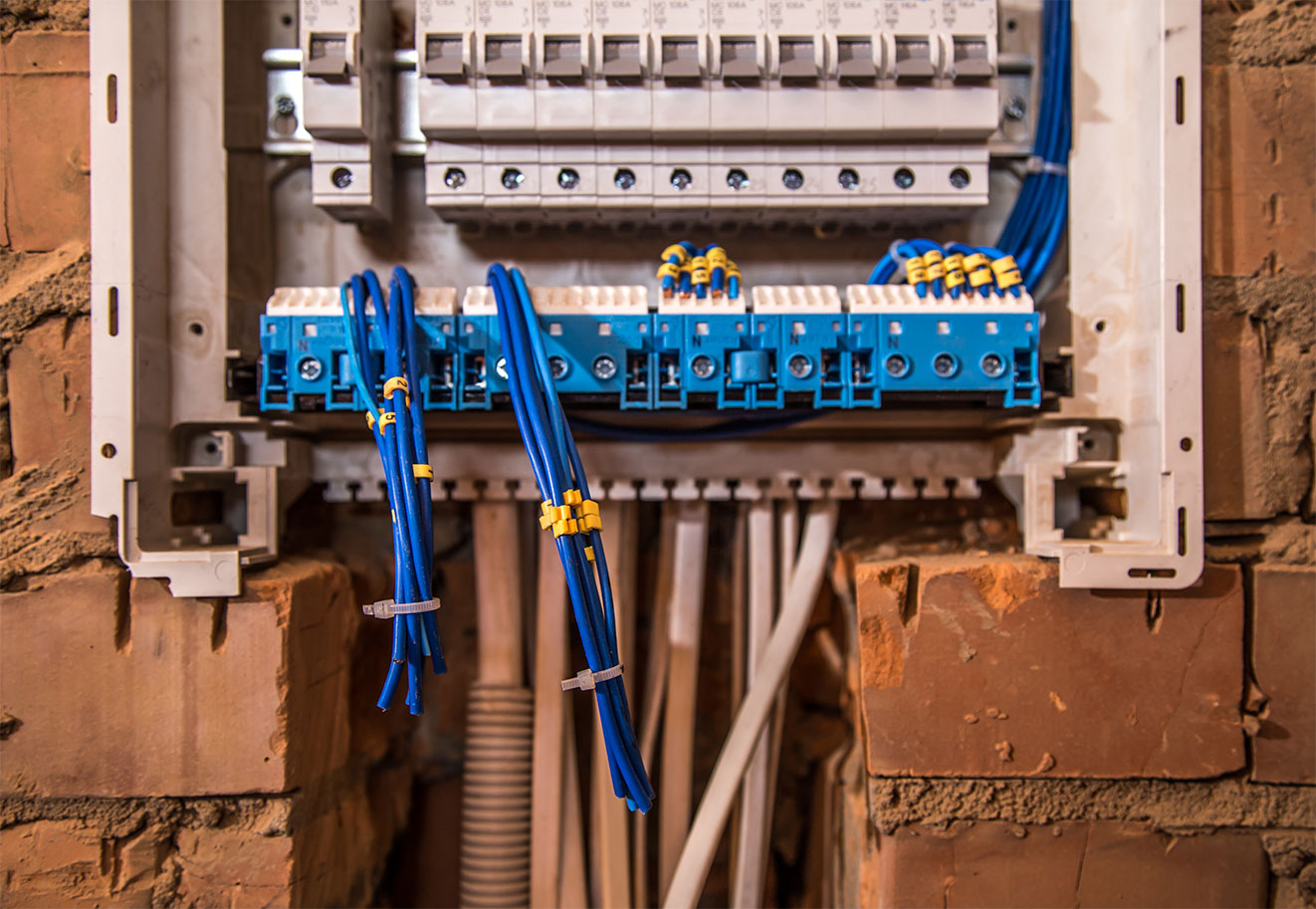

Automated systems can include:

-

Safety sensors

-

Access control mechanisms

-

Smart emergency shutdowns

-

Safety data logging

Safety becomes proactive, not just reactive.

7. Streamline Data Tracking and Performance Insights

Each automated operation generates data. When centralized using analytics or supervisory software, this data provides real-time visibility into industrial processes.

This enables companies to:

-

Predict breakdowns

-

Optimize cycle times

-

Set performance KPIs.

-

Improve decision-making

When paired with AI, automation creates intelligent and agile factories.

Conclusion

Industrial automation is no longer optional for Quebec-based companies looking to stand out; it’s a necessity. It improves operations, lowers costs, boosts productivity, and empowers teams.

At Groupe BEI, we support businesses at every stage of their digital transformation with customized solutions tailored to real operational needs.