Electric arcs, also known as “arc flashes,” represent a major hazard in industrial environments. These events can result in serious injuries, fires, and significant property damage. Understanding the dangers associated with arc flashes is essential for implementing effective prevention measures in the management of industrial electrical equipment.

Understanding the Arc Flash Phenomenon

What is an arc flash?

An arc flash is a sudden and intense electrical discharge that occurs when an electric current passes through an air gap between two conductors. This phenomenon produces a bright light, extreme heat, and a shockwave, all of which can cause severe burns and extensive damage to equipment.

Common Causes of Arc Flashes

Several factors can lead to arc flashes, including:

-

Overcurrent: Electrical overload can raise the temperature of conductors, leading to an arc flash.

-

Short circuit: An accidental contact between two conductors of opposite polarity can result in a high-intensity discharge.

-

Insulation failure: Degraded insulation may allow current to escape and trigger an arc flash.

-

Risks Associated with Arc Flashes

Physical and Neurological Consequences

Arc flashes can lead to severe injuries, including:

-

Burns: The intense heat generated can cause third-degree burns.

-

Electrocution: Current passing through the body may lead to cardiac arrest.

-

Electric shock: The discharge can result in internal injuries and neurological disorders.

Material and Financial Impacts

In addition to health risks, arc flashes can cause:

-

Fires: The heat produced may ignite surrounding materials.

-

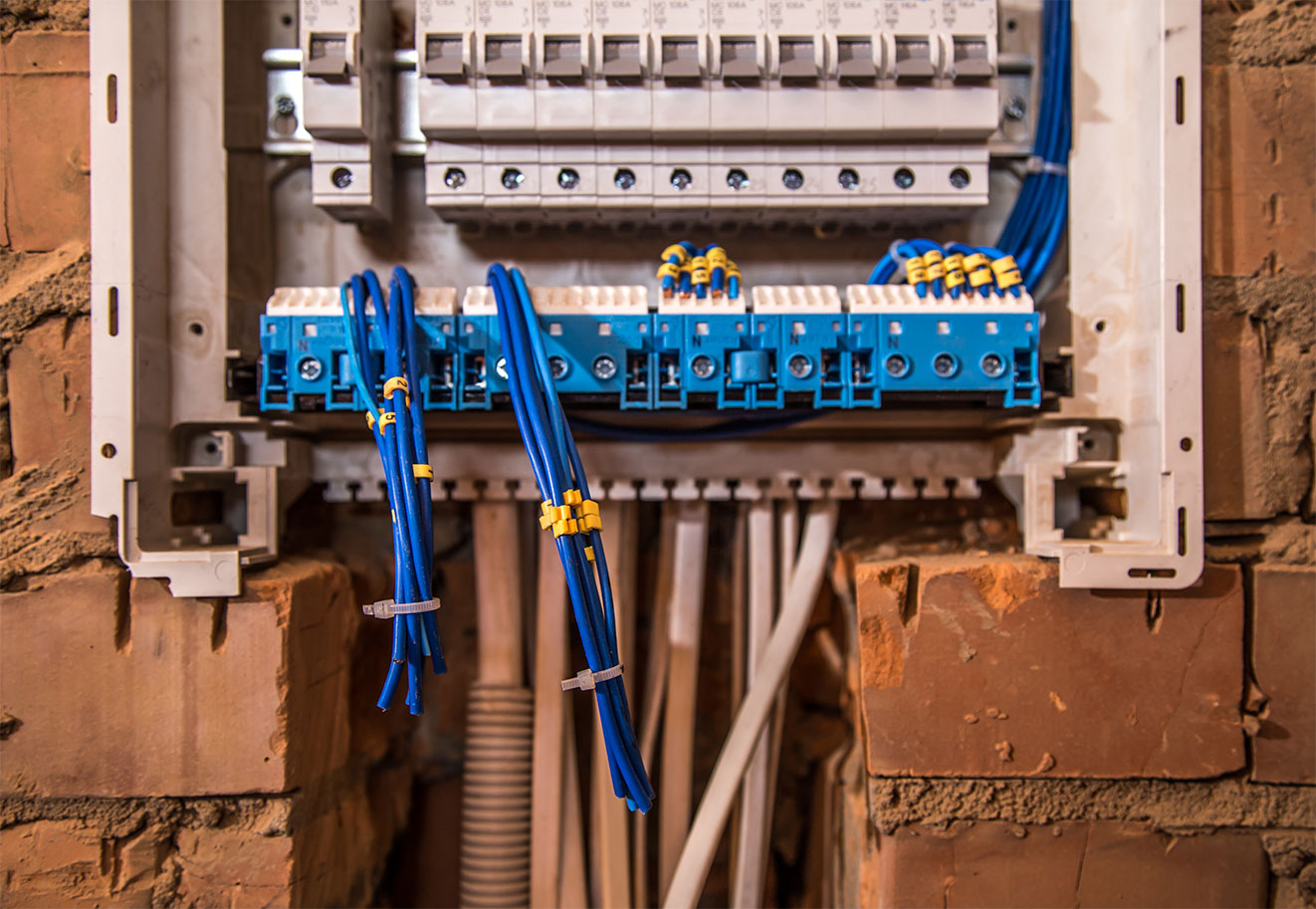

Equipment destruction: Arc flashes can severely damage or completely destroy electrical components.

-

Production loss: Downtime caused by damage can lead to substantial financial losses.

Protective Measures Against Arc Flashes in Industrial Settings

Workplace Risk Assessment

A thorough assessment must be conducted to identify potential hazards and high-risk areas. Conducting a risk assessment is a critical step in determining appropriate protection measures and ensuring electrical safety in the workplace.

Use of Personal Protective Equipment (PPE)

Wearing appropriate PPE, such as flame-resistant clothing, insulated gloves, and protective face shields, can significantly reduce the risk of injury in the event of an arc flash.

Regular maintenance is essential.

Routine maintenance is essential to detect and correct faults that could lead to arc flash incidents.

Recommendations for Electrical Risk Prevention

Whether handled internally or with the support of an external partner, assistance from an industrial electricity expert is recommended to mitigate arc flash risks and ensure worker safety. Key actions include:

-

Risk assessment: Analyzing installations to identify risk areas.

-

Personnel training: Raising awareness about hazards, prevention measures, and adapting work procedures.

-

Preventive maintenance: Inspecting and servicing electrical equipment regularly.

Arc flashes represent a serious electrical hazard in industrial environments. A thorough understanding of the risks, combined with the implementation of effective preventive measures, is essential to safeguard workers and facilities. Groupe BEI stands as a trusted partner to support companies in managing these risks.