Electricity powers everything in the industrial sector machines, production systems, lighting, and more. While essential, it also poses serious risks to health and safety at work. Electrical hazards can cause severe injuries, fires, production downtime, or even fatalities. That’s why implementing effective and compliant preventive measures is crucial.

The main electrical risks in industrial settings

Risk of electric shock

Electric shocks occur when someone comes into direct or indirect contact with voltage. This can lead to serious burns, cardiac arrest, or internal injuries. Common causes include:

-

Exposed or damaged wires

-

Faulty equipment

-

Poor insulation

-

Lack of lockout procedures before working on live systems

Risk of electrocution

Electrocution is the most severe outcome of electric shock and is often fatal. It happens when electric current passes through a vital organ. These accidents usually occur when workers lack training or fail to use proper protective equipment.

Risk of electrical fires

Arc flashes, overheating, or short circuits can easily spark fires. Frequent causes include

-

Overloads and short circuits

-

Flammable dust inside electrical cabinets

-

Loose or overheated connections

-

Improper grounding

Real-life example: An arc flash inside a distribution panel started a nighttime fire at a processing plant. Thanks to preventive measures, the damage was contained, but production was halted for 36 hours.

How to prevent electrical risks in a factory

Preventive maintenance of electrical systems

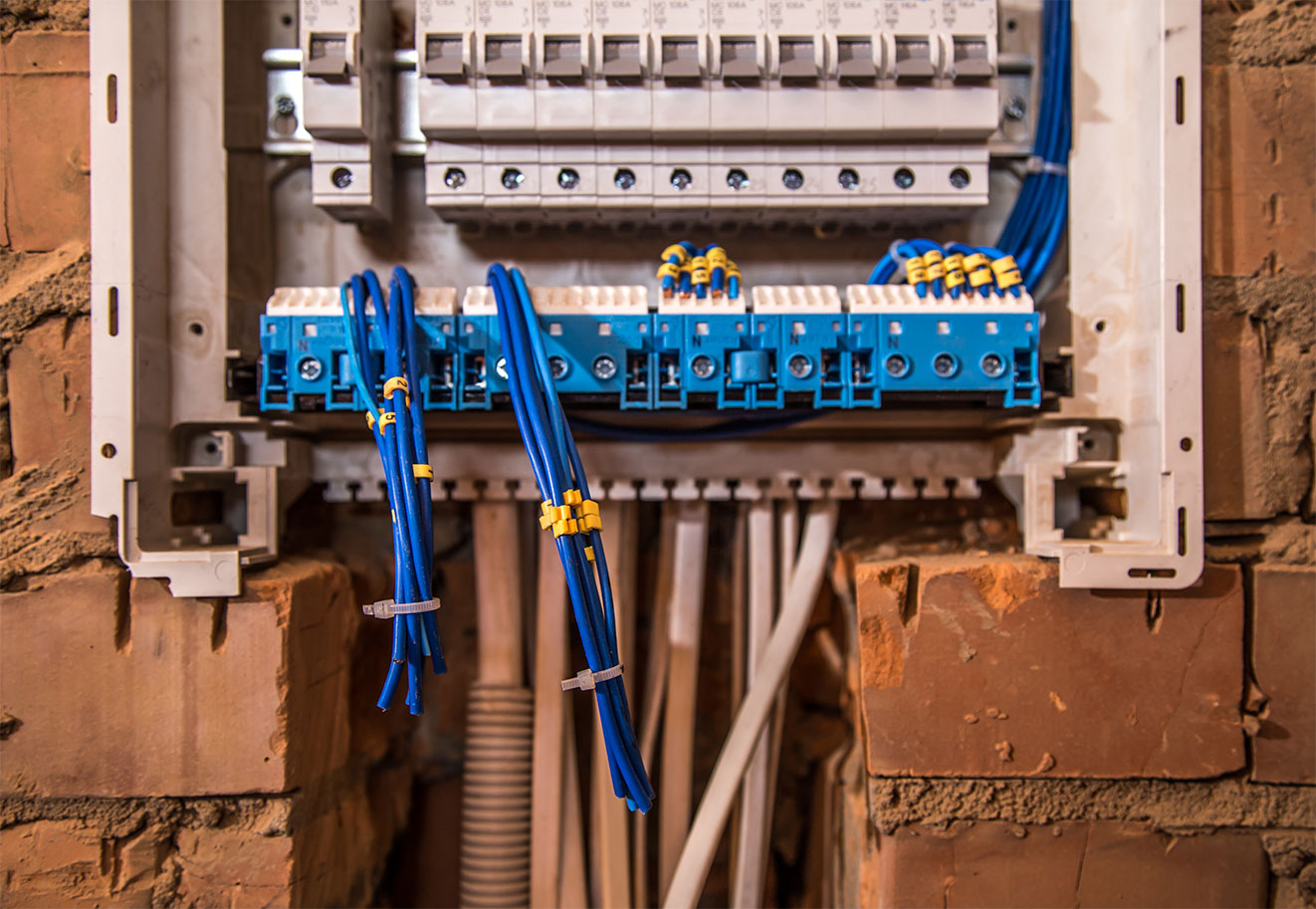

Preventive maintenance helps reduce the risk of electrical fires before they occur. It involves

-

Regular inspections of panels, breakers, fuses, and relays

-

Checking the tightness of all connections

-

Ground continuity tests

-

Replacing aging components

With Groupe BEI, businesses can implement maintenance protocols that meet all legal and safety standards.

Continuous monitoring of electrical systems

Advanced technology enables real-time monitoring to detect:

-

Voltage spikes

-

Abnormal temperature increases

-

Current leaks or insulation failures

These real-time data alerts help technicians take action before an incident occurs. Groupe BEI integrates this type of smart monitoring into its Industry 4.0 approach.

Safety training and procedures

Training is critical for anyone working on or near electrical installations. Workers must be

-

Trained in first aid for electric shocks

-

Informed about lockout/tagout procedures

-

Proper personal protective equipment such as insulating gloves, face shields, and rubber mats is essential.

-

Aware of signage and danger zones

Groupe BEI offers tailored training sessions designed for high-risk industrial environments.

Safety starts with proper system design

Safety starts at the design stage. Key practices include

-

Choosing the right residual-current circuit breakers

-

Ensuring proper ventilation for electrical enclosures

-

Separating power and control circuits

-

Using certified and shielded cables

These design choices help minimize exposure to electrical hazards from the start.

Creating a safer work environment

Electrical hazards should never be taken lightly. An effective prevention strategy relies on three pillars:

-

Routine preventive maintenance

-

Smart equipment monitoring

-

Ongoing employee training

By adopting these best practices, industrial companies can protect their workers, secure their assets, and reduce operational downtime.

Groupe BEI helps factories implement end-to-end electrical safety solutions.